- Libnodave S7-1200 Rack Slot Tray

- Libnodave S7-1200 Rack Slot Wall Mount

- Libnodave S7-1200 Rack Slot Machine

- Libnodave S7-1200 Rack Slot Rack

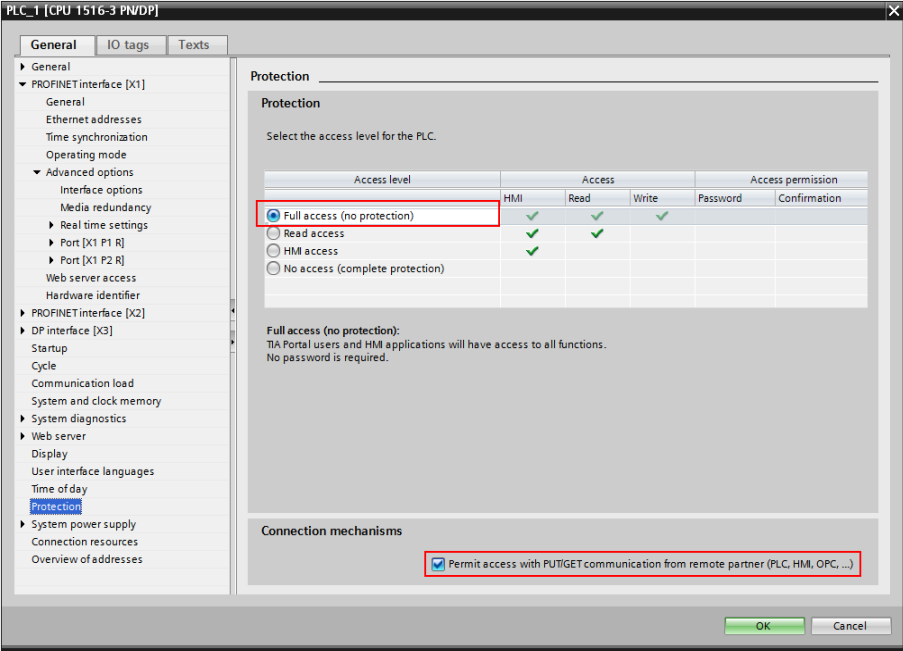

I have a weird problem with my Connection from C# to my Simatic S7-1200. I am using LibNoDave to connect and i want to set bits of my SPS with the C#-program. This is working just fine but it only works 9 times and then the writeBytes(.) function returns -1025 and not 0. Rack 0 CPU slot 1 On-line simulator Yes Multi-HMI connect Yes (Max:3 HMI) PLC Setting: 1. In S7-1200 program software create PLC program and tag and then download to PLC. Select Go offline, EasyBuilder will connect to PLC and get tag data. In PLC type select “SIEMENS S7-1200 (Ethernet)”.

This manual is divided in six chapters (not counting this introduction). The first chapter introduces the concepts and features of the s7nodave device support for EPICS. The second chapter describes the few steps needed to start an IOC project making use of s7nodave. The third chapter describes the IOC shell commands supported by s7nodave. Subsequently, the fourth chapter explains the various record types supported by s7nodave. Finally, the fifth chapter explains how to use poll groups.

If you have used this software before and are upgrading to a newer version, you might find the appendix useful that describes the changes that have been made in recent version and how you might need to update your project to match these changes. been made compared

| Warning |

|---|

When using this software to connect to a PLC, disconnect all external equipment from the PLC before trying to establish a connection. This software can overwrite variables in the PLC memory or even parts of the program running in the PLC. Therefore outputs of the PLC might show unpredictable behavior. There are a lot of different PLC types and depending on the type of the PLC, its configuration, the type of the host machine used for the EPICS IOC, the host machine's configuration and the EPICS IOC's configuration, this software might have very different, potentially unwanted results. It is always the responsibility of the user using this software to ensure, that its use is safe and complies with local regulation before connecting any equipment to the PLC. Violations of this rules might result in equipment being damaged or even persons being injured by misbehaving equipment. |

I have a RevolutionPI and i want to read data from a S7-1200 PLC.

From Pictory, i use virtual device REVPi7 but i'm not sure to set the editor value correctly.

Libnodave S7-1200 Rack Slot Tray

Values are:PLC IP: 192.9.200.206

Local_TSAP: 0 ????

Remote TSAP: 0 ????

Conn_Type: PG

PLC Rack: 0

Libnodave S7-1200 Rack Slot Wall Mount

PLC Slot: 1PLC Type: S7

Extended Data:

ACtion ID: 1

ACtion ID: 1Data Direction: Read

Libnodave S7-1200 Rack Slot Machine

Memory Area: ? (I need to read integer value)

DB#: The DB where i wantg to read data is DB20

Start: 1 or 40001?

Number / Size: 1 or 2 if i want to use the first integer?

Device value : Input 1

i also tried to use Modbus Master.

The connection with PLC was OK but impossible to read any value because i cannot address a DB number using the Modbus Master.